APCO Digital Twin

Building a Live Digital Twin Platform for Smarter Plant Operations

About APCO Digital Twin

Apco is a leader in advanced process control and optimization, with a multidisciplinary team managing a wide range of technical and operational tasks. Digital Twin is a next-generation decision-support platform designed to optimize water treatment operations using advanced hybrid modeling, decision theory, and machine learning.

Industry

Environmental Engineering

Service

Technology Department as a Service

What We Did

Web Development

Custom Team

3 Full-Time Equivalent (3 Developers)

Results

Since its launch, the Digital Twin platform has delivered tangible benefits like

30%

reduction in decision-making time

by enabling smarter, data-driven chemical dosing and water source selection.

100%

transformation into an accessible web platform

giving water operators powerful optimization tools for daily operations.

3x

faster data interpretation

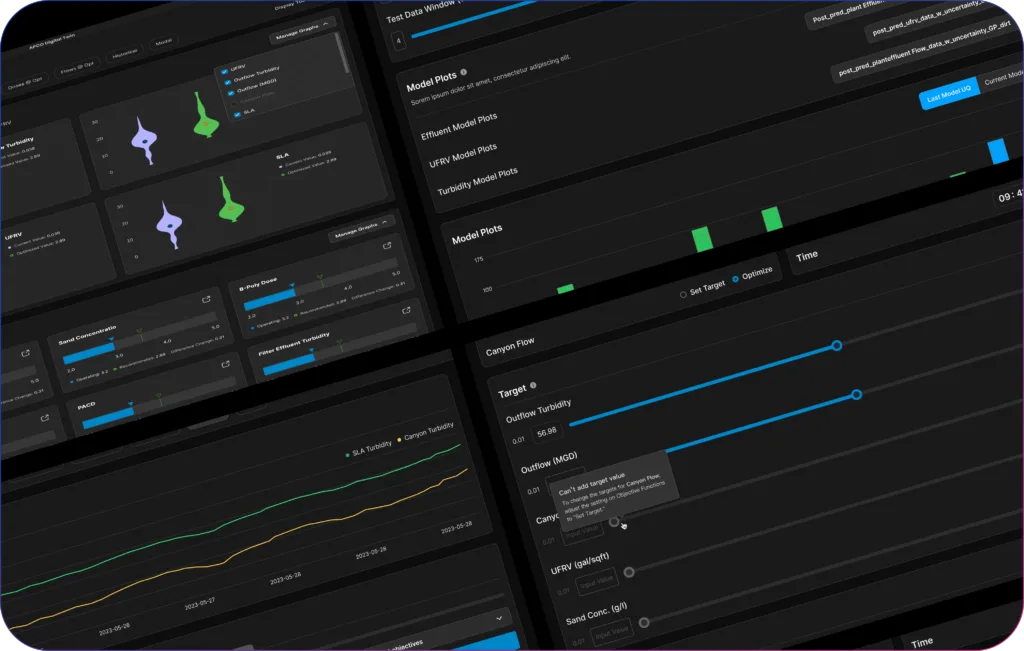

with intuitive dashboards visualizing uncertainty and system recommendations.

15%

lower operational costs

achieved through predictive optimization

Challenge

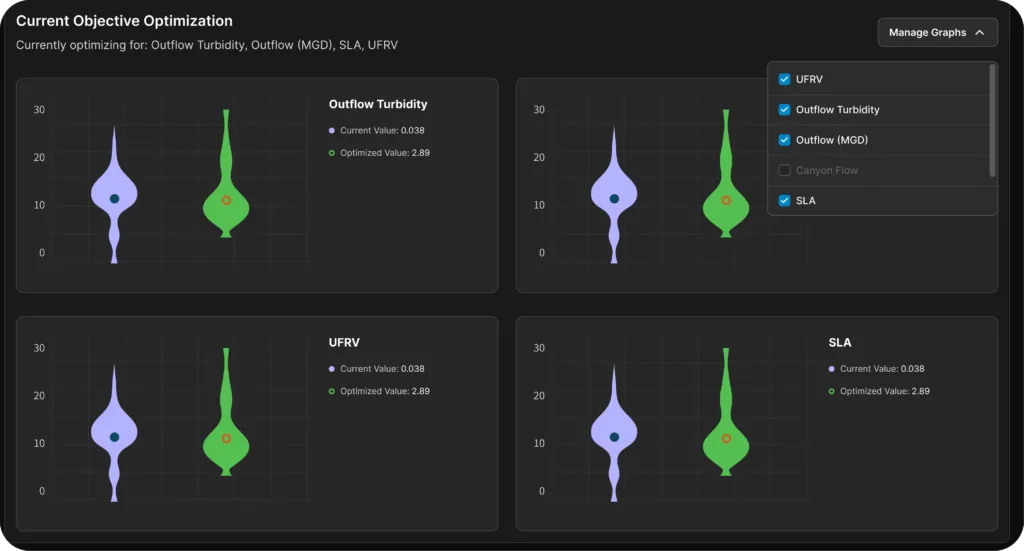

The original Digital Twin model, while promising in its research form, was built as a Python script that required technical knowledge to operate. This limited its usefulness for plant operators who needed real-time insights and an interface that aligned with their day-to-day workflows. The project stakeholders, including the Jordan Valley Water Conservancy District, APCO Inc., and the University of Utah, wanted to make the tool accessible to frontline teams at the Southeast Regional Water Treatment Plant. That meant turning an academic proof-of-concept into a secure, intuitive, and always-on web application.

Solution

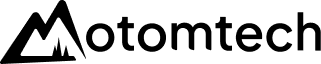

Motomtech’s Technology Department as a Service stepped in to convert the research prototype into a scalable, user-ready web platform. The development approach was executed in structured phases to ensure continuity, usability, and technical accuracy.

Phase 1

Conceptualization

We worked alongside researchers and plant personnel to understand the modeling logic, operational challenges, and user expectations. This included analyzing the existing codebase, defining functional requirements, and producing a visual blueprint for the web application interface.

Phase 2

Software Prototype

Our design team built an intuitive UI that simplified the complexity of the model output. The clickable prototype helped stakeholders visualize the platform’s key flows like the optimization selection, model execution, and result exploration.

Phase 3

Implementation

Once deployed, we continued refining the platform with feedback from SERWTP operators and the engineering team. Enhancements included improving visualizations, expanding model flexibility, and planning for live data integration from the treatment plant systems.

Phase 4

Maintenance & Enhancement

Once deployed, we continued refining the platform with feedback from SERWTP operators and the engineering team. Enhancements included improving visualizations, expanding model flexibility, and planning for live data integration from the treatment plant systems.

Technology Stack

To ensure a high-performance, scalable, and secure solution, Digital Twin was built using:

Backend & Infrastructure

Python Hosted web application

Frontend

Web-based interface built on custom Python framework

Testimonial

“Motomtech helped take an academic model and turn it into a solution that our operators can actually use every day. The new platform is fast, intuitive, and built for the real world. It’s helping us make better decisions, save money, and manage our resources more sustainably.”

Philip Smith,

CEO, Digital Twin