Apco Seeq

Real-Time Visibility at Scale: Co-Developing CLPM for APCO Engineers

About APCO CLPM

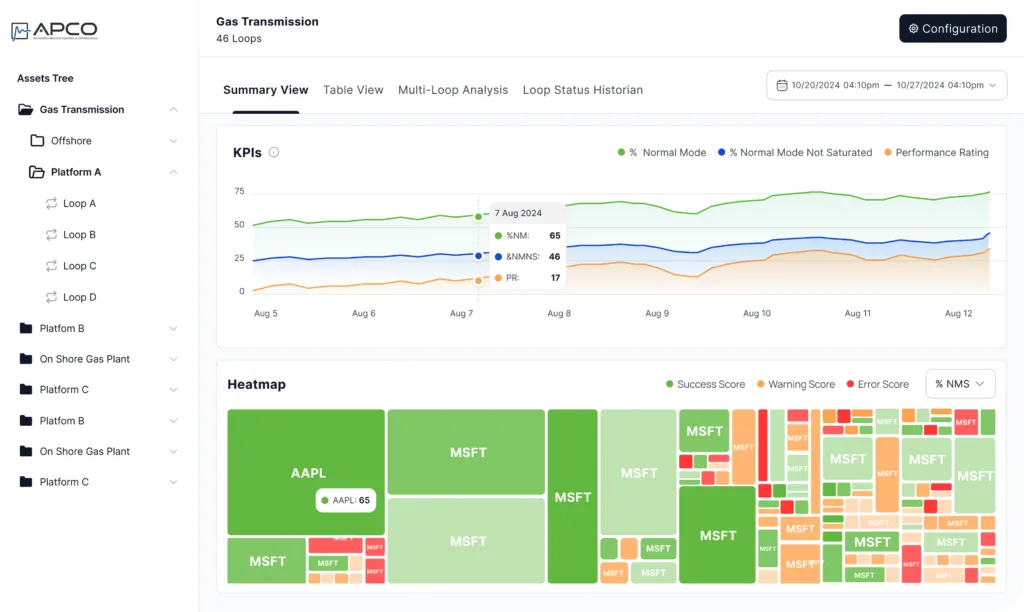

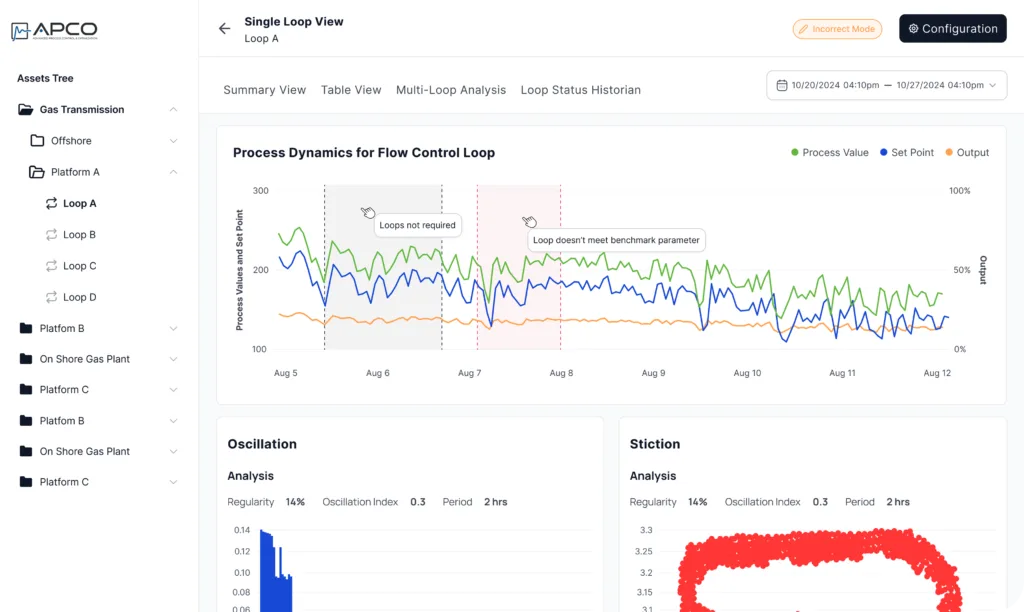

APCO is a leader in advanced process control and optimization, with a multidisciplinary team managing a wide range of technical and operational tasks. CLPM (Control Loop Performance Monitoring) is a powerful Seeq add-on developed by Motomtech in collaboration with APCO’s Process Engineering team. Designed to provide engineers with deep visibility into control loop behavior, the solution offers real-time insights into performance, benchmarks, and exceptions, all within Seeq’s familiar environment.

Industry

Manufacturing

Service

Technology Department as a Service

What We Did

Seeq Development

Custom Team

3 Full-Time Equivalent (3 Developers)

Results

Since its launch, CLPM has delivered tangible benefits like

70%

reduction in manual loop reviews

saving time and speeding up benchmark violation detection.

100%

real-time visibility

across control loops giving process engineers access to performance data.

3x

increase in team collaboration

with shared comments, contextual updates, and decision-making.

95%

consistency in benchmark tracking

ensuring clear standards for defining and responding to performance thresholds.

Challenge

The APCO Process Engineering team needed a more structured and interactive way to evaluate the performance of their plant’s control loops. Their current method of manual inspection made it difficult to catch deviations, benchmark performance, and track recurring issues efficiently. There was also a usability challenge: any new tool had to integrate directly into Seeq, the existing analytics platform used across the plant. A standalone solution wasn’t an option. The engineering team needed something lightweight, integrated, and built around how they actually work.

Solution

Motomtech’s Technology Department as a Service was brought in to transform the APCO team’s vision into a scalable product built directly within Seeq. Working closely with process engineers and internal developers, we approached the project in three phases:

Phase 1

Discovery & Concept Validation

We began by gathering domain-specific insights from APCO stakeholders to understand their workflows, data structures, and ideal output metrics. This early collaboration laid the foundation for a functional design that could live natively within Seeq’s Workbench environment.

Phase 2

UX Design & Front-End Development

Using Figma, our team designed a custom interface optimized for control loop monitoring. The design featured a high-level summary dashboard displaying KPIs and warning indicators, a sortable table view to track all loop metrics and benchmark compliance, and a detailed Single Loop View for drilling down into PV, SP, OP, and Mode trend analysis. Interactive elements like status updates, comment threads, and CSV-based configuration tools were built in to support collaboration and speed up engineering feedback cycles.

Phase 3

Integration & Release

The add-on was implemented directly within Seeq using Python and custom scripting. Engineers were able to set and save benchmark thresholds, identify underperforming loops in real time, filter by plant area or loop category, and log insights with contextual status updates. With the add-on now live and fully integrated, APCO engineers actively improved loop efficiency, reduced operational variability, and shortened troubleshooting cycles. A second version of the add-on is already in development to introduce even more advanced analytical capabilities.

Technology Stack

To ensure a high-performance, scalable, and secure solution, CLPM was built using:

Backend & Platform

Python Seeq

Testimonial

"CLPM has completely changed how we track control loop performance. What used to be a manual and fragmented task is now streamlined, visual, and much easier to manage. The Motomtech team really listened to what we needed and delivered a tool that fits right into our workflow."

Eric Smith,

President, APCO