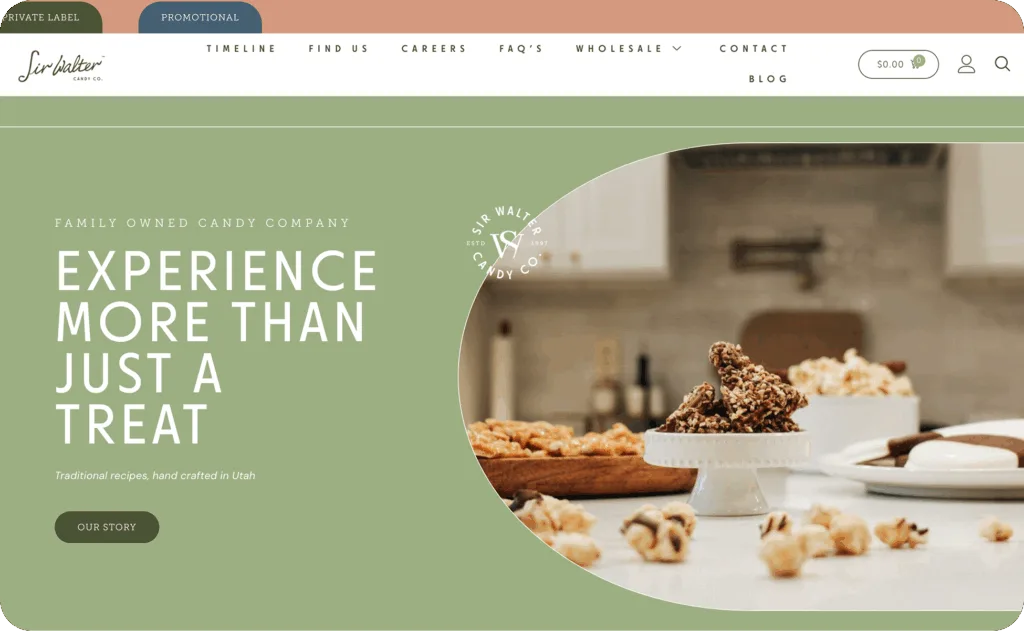

About Sir Walter Candy

Sir Walter Candy is a premium chocolate manufacturer known for its craftsmanship and dedication to quality. As the company expanded, internal operations became increasingly complex, highlighting inefficiencies that slowed production and order management. To scale sustainably, Sir Walter Candy sought a partner who could analyze their workflows and propose a tailored digital solution.

Industry

What We Did

Product Conceptualization

Custom Team

1 Full-Time Equivalent (PO, Ux/UI, Software Architect)

Results

Since the report, Sir Walter Candy has seen tangible benefits like

35%

efficiency gain

identified across internal workflows

50%

faster order processing

forecast with a digital solution

20%

reduction in

operational costs through automation

1

Clear roadmap

for building a custom application

Challenge

Sir Walter Candy’s internal processes relied on fragmented, manual methods that created bottlenecks and inefficiencies. Without a clear system to manage production, orders, and inventory in an integrated way, the company risked slowing growth and reducing its competitive edge.

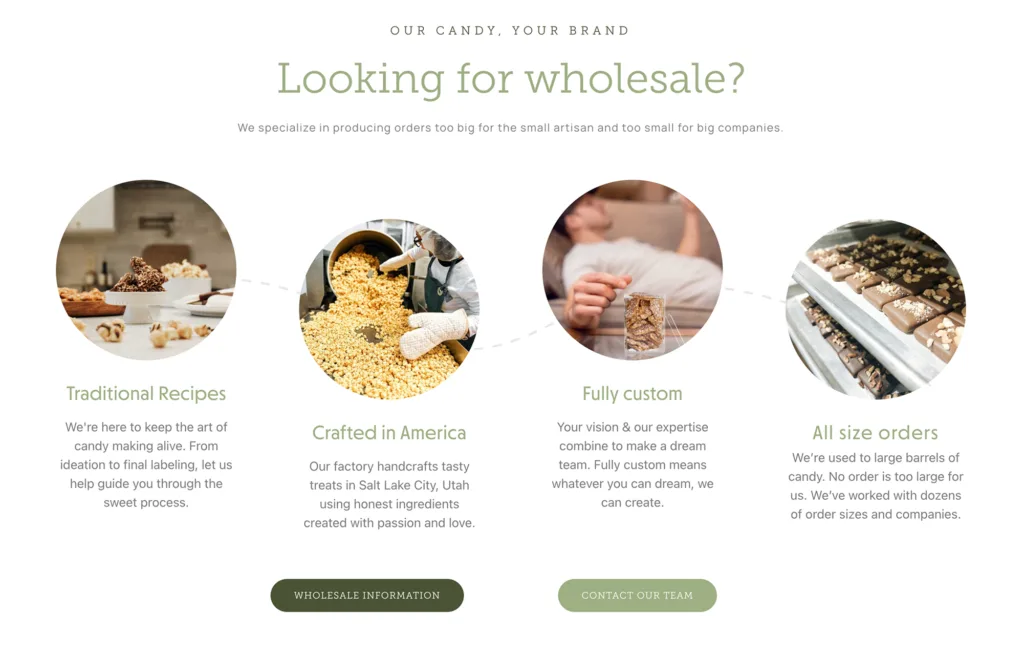

Solution

Motomtech partnered with Sir Walter Candy through its Technology Department as a Service model to conduct a comprehensive conceptualization study

Phase 1

Conceptualization

The team mapped out the company’s operational workflows, identified gaps, and highlighted inefficiencies. From this analysis, Motomtech delivered a detailed conceptualization report showing how a custom software application could centralize operations, streamline production, and reduce manual errors. This report provided the foundation for a scalable digital roadmap, helping Sir Walter Candy plan confidently for the next phase of development.

Technology Stack

To ensure a high-performance, scalable, and secure solution, Sir Walter Candy was conceptualized using:

Design & Planning

Miro Figma Lucidchart Confluence

Testimonial

Motomtech opened our eyes to what was possible. Their conceptualization report showed us where we were losing time and money, and more importantly, how a custom application could transform our operations. It gave us clarity and confidence for the future

Alfonso Porras,

Founder, Sir Walter Candy